With the ever-increasing drive to preserve and work with the environment our clients are expanding their test requirements. An example of this is equipment that simulates wind over ocean wave tanks. This can allow researchers to combine the effects of wind and water on marine vessels, wind turbine and other test subjects.

ATE are proud to be associated with a project that it has undertaken for the University of Plymouth.

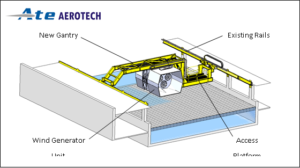

The images show a (WGU) Wind Generator System configuration at an Ocean Basin facility in the UK. The two existing rails at each side of the test tank interface to the gantry that supports the WGU. Wheels at each end of the gantry sit on the rails and allow the system to be manually moved in the X axis. Automated clamps prevent roller rotation to maintain the X position when it has been set.

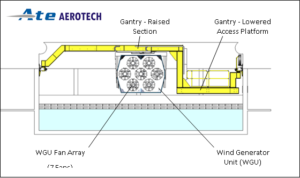

The gantry is configured to incorporate a lowered access platform and a raised section that supports the WGU. The platform allows access to the equipment and provides an open area for items to be moved across the gantry using the facility crane.

Y rails mounted within the structure of the raised section and a carriage are fitted so that it can move laterally across the tank. Rollers are used for carriage movement and automated clamps retain the Y position. A geared slewing ring is fitted to the carriage, and forms the attachment for the Z guiding structure of the WGU. A yaw drive system rotates the slewing ring to provide yaw motion of the WGU. Guiding structure surrounds the bulkhead section of the WGU that houses a series of fans. Guides attached to the structure and a Z motion system allow the bulkhead to move in the Z axis.

A front view of the WGS looking into the wind, is shown below. This demonstrates the lowered Platform and raised section of the gantry and the WGU centrally positioned. The WGU configuration consists of a multi-fan system that blows profiled air across the Ocean Basin. Nine fans with flow straighteners are mounted as an array within the Bulkhead. An intake section will is mounted at the rear of the bulkhead whereas a settling chamber and conditioning elements are fitted at the front nozzle.