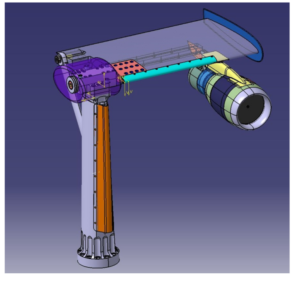

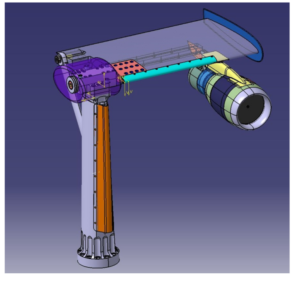

EMPAS Electric Motor Powered Aero-engine Simulator

The potential use of electric motors to power engine simulators on wind tunnel models of commercial aircraft has been studied for some years at the QinetiQ 5m Wind Tunnel at Farnborough. Recently, motors with the required power density have become available, and design and production of a prototype engine simulator is currently being undertaken.

Some of the benefits are:

- flexible power cabling as opposed to the high pressure pipes associated with traditional Turbine Powered Simulators (TPS).

- cabling will be contained within the model,

- normal weight tare should account for any induced resistance on the balance.

- efficiency increase as power supply will be directly fed from an electrical supply.

- test duration for similar reasons as above.

- This will deliver a constant flow of energy and eliminate the need for inefficient and expensive industrial plant to pressurise the working fluid as is currently the case.

- Consequently, the ease of operation of this technique will be improved, with a subsequent increase in its use across many wind tunnels.

- More realistic bypass jet stream temperature.

- It is expected that the overall control of the simulator will be improved as there will not be the need to balance turbine and tunnel airflows.

This original concept was developed with the support of UK Government ATI funding and was undertaken by a consortium consisting of QinetiQ, Boeing, Collins Aerospace, University of Surrey and ATE.