An alternative option is the ATE PPT.

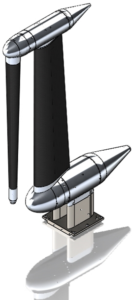

This solution utilises rotary movement translated into horizontal and vertical motion for two-dimensional (Y & Z) surveying. To provide volumetric survey capability, the device can be mounted on to a motorised or manually driven X rail system.

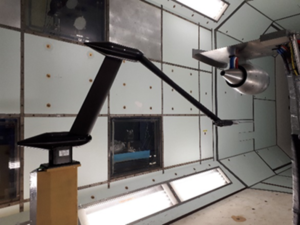

The PPT is particularly useful in closed test section application where there is restricted operational space.

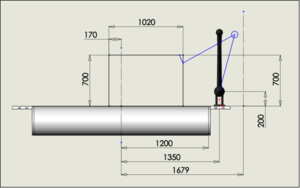

Typical Survey Areas:

Probe positioning is achieved by a combination of rotary motions and the geometry is arranged to span the defined survey area. The illustration below shows a view into wind with the PPT mounted on the right-hand side of the test section at 1350mm from the centre line. The required survey area rectangle is shown as 1020mm (Y) x 700mm (Z), overlapping the centre line by 170mm

Loads imposed upon the arms and drives are much higher in this situation, – Initial designs of the PPT were for F1 applications. The Aerospace applications require the PPT to operate in higher air flow speeds. Where an EMPAS* unit is being tested, the nacelle discharge considerably increases the dynamic loads that the unit needed to withstand and operate in. The maximum nacelle discharge velocity is in the region of (200 m/s). For a typical F1 application the test section speed is between (70 to 80 m/s)

Therefore, the design used needed to minimise the aerodynamic impact from rotary arms whilst maintaining structural integrity and minimise deflection.